If you are considering metal injection molding mim or ceramic injection molding cim for the production of your components take a look at our extensive design guide for end users.

What is ceramic injection molding and describe the process.

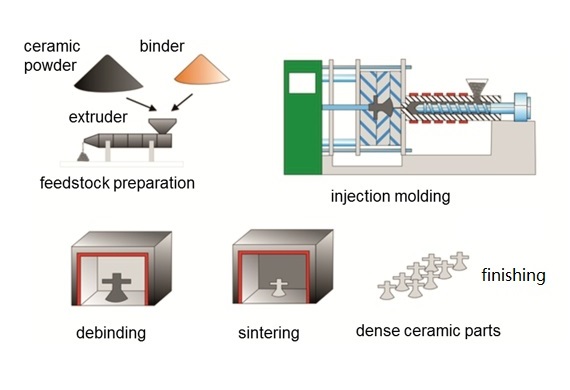

Feedstock preparation injection molding debinding process and sintering fig.

This process also gives a low grade of toleration.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

The steps in this process are described in greater detail in the next section.

The ceramic injection molding is very suitable for high volume production of complex design with tight tolerances like bonding capillaries.

The injection molding process requires the use of an injection molding machine raw plastic material and a mold.

Equipment used for injection molding is similar to that of extrusion.

The plastic is melted in the injection molding machine and then injected into the mold where it cools and solidifies into the final part.

The patterns that ceramic mold uses are plaster plastic wood metal rubber etc the pattern is the shape body of the desired part.

But the process is different.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

The 4 basic processes of mixing injection debinding and sintering are similar to that of metal injection molding mim.

The feed material used for injection molding contains a mixture of ceramic powder with thermoplastic polymer plasticizer wetting agent antifoaming agent.

Ceramic injection molding cim is a manufacturing process used to mass produce precision ceramic components with complex geometries.

Process flow for capillary manufacturing process stage 1.

It is an effective way of manufacturing complex precision components with the highest degree of repeatability and reproducibility.

1 when powder technologies are in question the key step in production process is choosing the adequate ceramic powder.

A guide to the technology for end users and designers.

The ceramic molding process is a production method which guarantees the precision required and also gives a good surface finish using a high temperature method to better structure and shape parts.