Glued laminated timber also abbreviated glulam is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable moisture resistant structural adhesives.

What is laminated bamboo lumber and bamboo glulam what is the basic difference.

Figure 3 details the manufacturing process and illustrates the difference between the two products with bamboo scrimber primarily.

Builders often refer collectively to all types of laminated beams or other laminated structural wood materials as glulams.

With construction advantages including higher design values improved overall performance and cost savings glulam is the product of choice for projects ranging from residential beams and headers to commercial.

Laminated composites plywood and veneered wood are all laminated wood products.

The difference is how they re made.

Laminated veneer lumber lvl is a commonly available engineered product that is manufactured similarly to psl.

Glulam has been shown to be as strong as steel with greater strength and stability than similarly sized standard dimensional lumber.

This paper presents a study aimed to characterize the structural performance of laminated bamboo lumber lbl and bamboo glulam beams bgbs as a first step to evaluate their potential application as a structural material.

The difference in laminated wood products typically is the core of the material.

In comparison the material efficiency of glulam production in the usa is approximately 82 puettmann and wilson 2006.

A glulam is made with multiple layers of solid wood lumber bonded together with high strength adhesive to form a single structural unit.

The term glulam is an abbreviated term that stands for glue laminated timber.

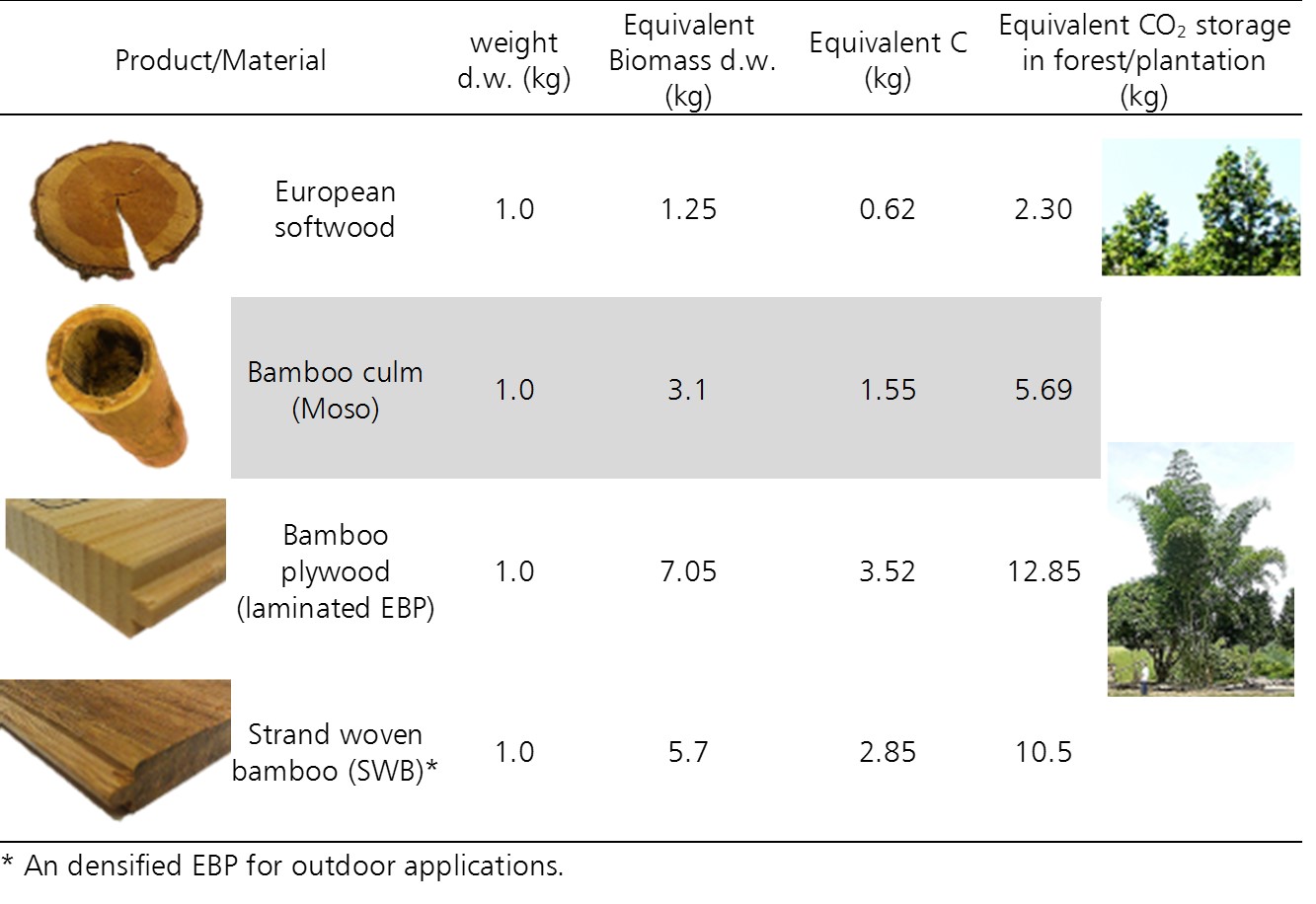

And is approximately 80 for bamboo scrimber and 30 for laminated bamboo van der lugt 2008.

Psl beams are generally more expensive than glulam lsl or lvl beams.

Download the glued laminated beam design tables form s475 provide recommended preliminary design loads for two of the most common glulam.

Two examples of engineered bamboo are bamboo scrimber and laminated bamboo bamboo scrimber also referred to as strand woven or parallel strand bamboo consists of crushed fibre bundles saturated in resin and compressed into a dense block the process is materially efficient utilising approximately 80 of raw inputs and produces a product with a janka hardness that is acceptable for.

Available sizes strengths and stiffnesses are similar to psl.

In north america the material providing the laminations is termed laminating stock or lamstock.